Rheonik Coriolis Mass Flow Meter

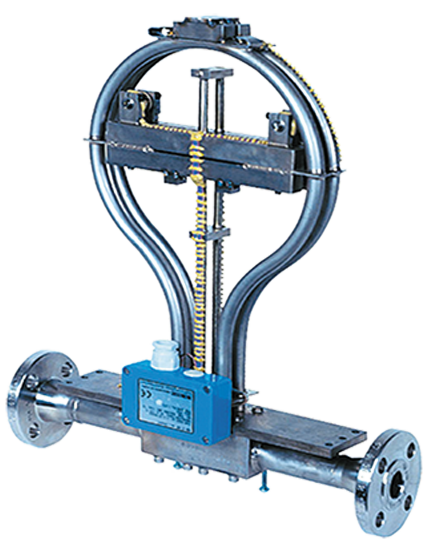

Beginning in 1984, Karl Kuppers began the design of a mass flowmeter based upon the Coriolis effect that later became the patented Omega tube Coriolis Mass Flowmeter manufactured by Rheonik today.

The Rheonik range with its unique Omega tube design allowas the most challenging mass flow metering applications to be solved.

The Omega tube has a torsional oscillation movement rather than the bending motion

associated with other, more conventional Coriolismeter designs.

The unique mechanical arrangement of the Omega tube meter allows the use of tubing with heavier wall thickness giving higher pressure ratings, combating abrasion and erosion and eliminating the requirement for the secondary

pressure containment found with conventional designs.

The use of the Coriolis effect as a technique for liquid and gas mass flow measurement was firmly established over 20 years ago. Since then,

a number of different designs have been produced. With the tremendous electric signal processing technology advances that has been made, Coriolis mass flowmeters have become highly accurate and reliable instruments.

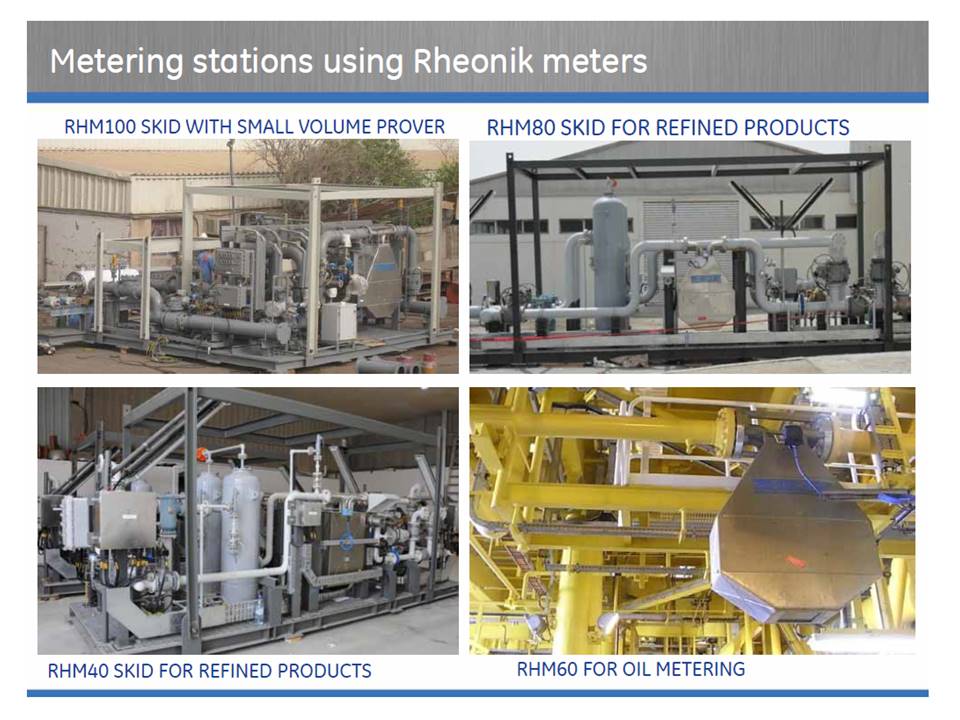

Rheonik remain at the forefront of this technology and now produce the world's largest and most comprehensive range of meters. Only the Rheonik range has all of the following features:

Liquid, sludge and gas measurement capability

Extreme resistance to gas bubbles entrained in the process stream when compared to conventional Coriolis meters

Variety of sizes cover flow rates from as low as 0.03 kg/h up to 1,500,000 kg/hr (up to 12" / DN300

Pressure ratings up to 900bar, Temperature ratings from -225° to +400°C

Fiscal/cutody transfer approvals (MID/NMI)

ATEX and CSA hazardous area approvals covering most of the world

With the wide range of models we can match the most cost-effective size to your application.

Rheonik Coriolis Flowmeter

Rheonik Coriolis Flowmeter