KRAL Flow Meter Technology

Precision measurement suitable for heavy oil.

Precision measurement suitable for heavy oil.

Other providers of systems for fuel consumption measurement mainly advertise their pretty electronic displays. The flowmeters which measure the fuel are often not mentioned at all. It is not the electronic display but the meter which decides how useful the measurement is.

KRAL Volumeter are the flowmeters of KRAL fuel consumption measurement. Their cases are of nodular cast iron, which is suitable for heavy oil. The steel spindles are nitrated. For HFO, KRAL recommends hybrid bearings with ceramic balls. KRAL Volumeter are always installed behind the filter of the booster module. This filtering protects the injection pumps and therefore also the flowmeters. For more safety when they are put into operation, Volumeter have dirt pans.

Temperature compensation.

Fuel is bunkered in volume units. Specific fuel consumption is a mass unit. Using the temperature sensor and density table, the measured values of the KRAL Volumeter can be converted into mass units and displayed.

Even in the case of preheated heavy oil, there are temperature differences between the forward and return flows. With KRAL temperature compensation, the temperature differences are taken into account in the precise measured value formation. Temperature compensation is a function of the KRAL electronic units.

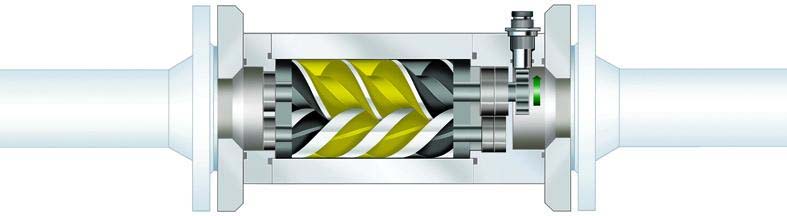

High precision measuring chamber.

<

KRAL has great skill in spindle production. The spindles are precision parts. They are the basis of very precise fuel measurement.

Pressure pulse compensation.

Injection pumps cause pressure pulses in the fuel lines, which may cause a reversal of the direction of flow. With the flow direction sensor in addition to the flow sensor, a second signal of the spindle rotation is monitored. From the phase difference, the KRAL electronic system detects the direction of rotation of the spindles. Flows in the wrong direction are measured correctly and used to calculate the consumption value precisely.